微信公众号

Enpat Jiangsu Environmental Protection Industry Co., Ltd. is a British enterprise with strong strength in the Asian industry. Adhering to the new era goal concept of making greater contribution to the environmental cause, it produces advanced high energy-saving environmental protection renewable material processing equipment, develops clean renewable energy, solves the main environmental problems faced by human beings, and makes greater contribution to the green of the earth.

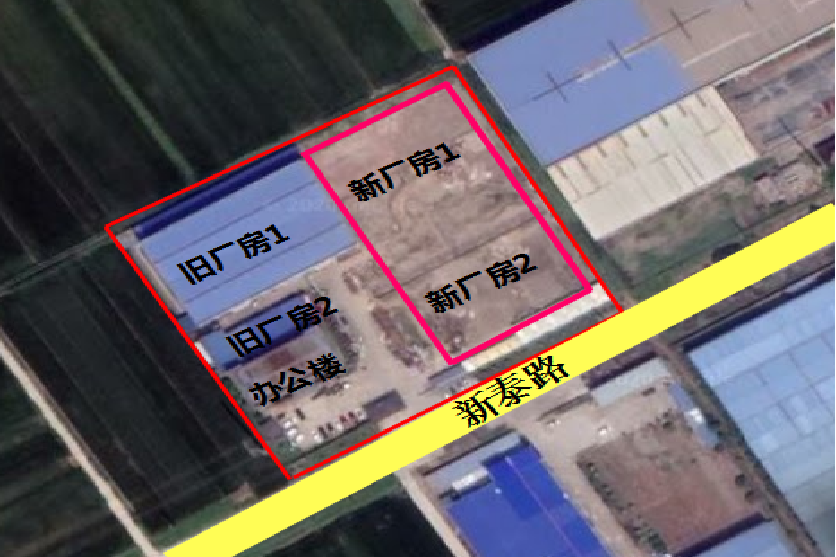

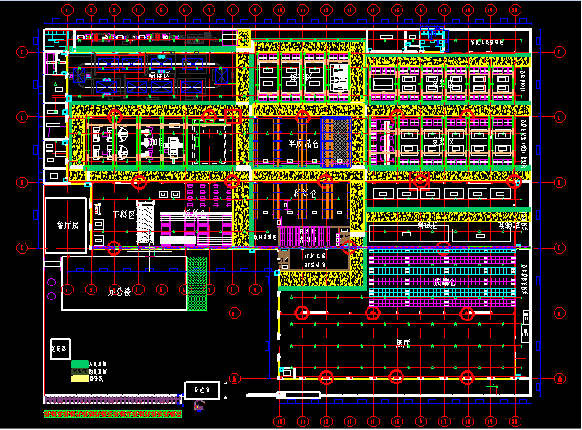

New plant planning project

The new factory is expanded on the scale of the existing factory. The new planning factory breaks the original production mode and logistics mode, adds the design concept of lean production, adds various automatic equipment, and adds the factory exhibition hall, etc., covering a total area of 12499 square meters, including 1 ? workshop of 2160 square meters, 2 ? workshop of 8640 square meters, 3 ? workshop of 313 square meters.

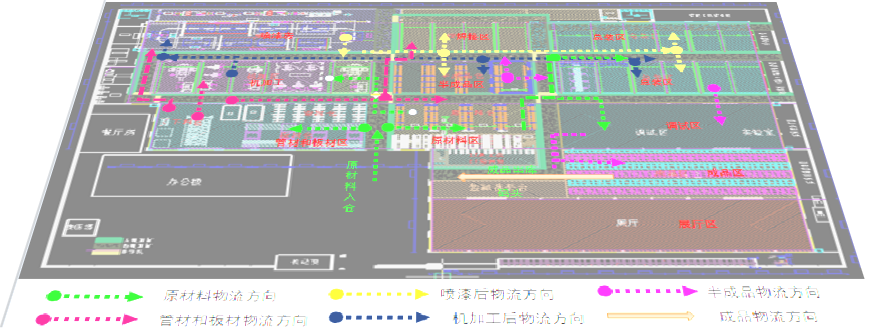

In the future, the new factory will be planned according to the annual output value of 575 million RMB. The planning contents include raw materials, cutting, welding, painting, fine assembly, final assembly, debugging and packaging, and finished product delivery. The whole process is planned according to the lean streamline scheme to meet the future development needs of diversification and high output value.

The new factory layout is optimized from the chaotic layout without obvious flow direction to the matrix layout based on the product process characteristics. It focuses on solving the problems of unsmooth logistics handling, circuitous path and many WIPs in the production process, and optimizing the storage mode of raw materials, semi-finished products and finished products. In the mechanical processing, welding, spraying and other processes, the introduction of full automation program, while saving people and efficiency, optimize the workshop working environment, reduce the workshop environment dust, odor and other pollution.

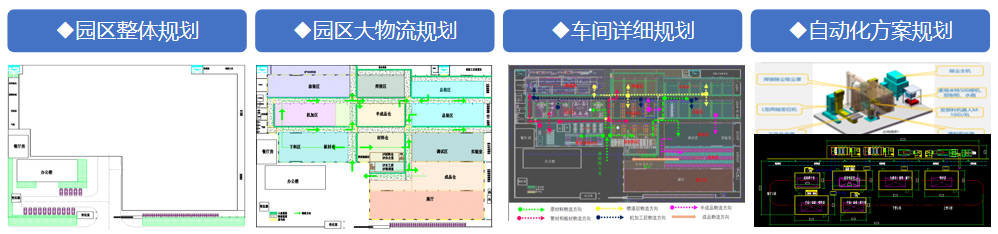

1. Overall planning of the park: according to the red line of the land and the building permit, and combined with the structure of the built plants, the peripheral auxiliary facilities of the park are planned;

2. Logistics planning of the park: according to the product categories and process flow of future planning, the overall layout of the park is planned based on the principle of separating people and vehicles.

3. Detailed workshop planning: calculate the area demand of each module according to the capacity planning, and confirm the detailed layout of each area in the workshop in combination with the process relevance review.

4. Automation scheme planning: analyze the specific process, plan the corresponding automation scheme and material turnover scheme.

5. Warehousing and logistics planning: focus on the planning of raw material warehousing, covering metal plate, structural parts, power construction, fasteners, seals and other raw material storage and delivery with different package specifications.

6. Auxiliary facilities planning: according to the planning capacity demand of the new plant, supporting the corresponding water resources, strong electricity, weak electricity, gas and other auxiliary facilities, as well as lighting, ventilation and cooling scheme planning.

7. Scheme hardware equipment selection: the new scheme is combined with the planning scheme to connect with the relevant hardware construction manufacturers, and clarify the relevant requirements, scheme planning, evaluation and hardware selection.

8. Visual scheme planning:

According to the planning scheme, carry out the visual scheme design of the project site, covering the park, workshop, auxiliary equipment, office and exhibition hall, and carry out training and propaganda to clarify the future implementation standards.

The planning project of NPT new factory takes two months. The intelligent team of fine industry has fully combined lean concept, breaks the traditional production mode, and introduces a flow production mode as a whole. Through the product, lean and automation, the logistics handling and in-process products quantity in the production process are reduced and the overall manufacturing capacity of NPT is improved. During the project development, it has been highly recognized and praised by the leaders and employees of the customers. The estimated benefits of the project are as follows: 1. The production efficiency is increased by 20%; 2. The quantity of workshop in process products is reduced by 30%; 3. The distance between the transportation is reduced by 50%; 4. The site utilization rate is increased by 40%; 5. The 5S and visual management level of the production site are significantly improved.

--- THE END ---

扫二维码 关注我们

官方咨询热线:4006966916

吴先生:15820605726

微信公众号

百乐博视频号

百乐博抖音号

天下统一热线:400-696-6916

广东公司:Jinggong Zhizao Digital Intelligence Industrial Park, Baohui Road, Lunjiao, Shunde District, Foshan City, Guangdong Province, China.

13077439821 屈先生

浙江公司:浙江省宁波市江北区前洋E商小镇北门一号楼414室

13077439821 屈先生

江苏公司:江苏省无锡市梁溪区清扬路333南长创业大厦603

13077439821 屈先生

安徽公司:合肥市高新区中安创谷A3A4号楼742室

13077439821 屈先生

天下统一效劳热线